Reducing Nonconformances

Reducing nonconformances in an organization is fairly easy to do, although it is impossible to eliminate them completely. It is however always better to prevent issues rather than reacting to them.

Construction Nonconformance

A construction quality control plan should contain a systematic process that can be used to manage construction nonconformances, whether they’re simple or difficult.

Manufacturing Nonconformances

Manufacturing nonconformances are products that don’t meet specifications established by regulators or manufacturers. Nonconformances are however not only defective physical products.

Non Conformance Management Software Benefits

Using Non conformance Management Software has many benefits, one of which is saving you energy and time.

How to Create a Nonconformance Report

Creating a nonconformance report is not that difficult. The 7 steps described in this article will go a long way in helping you write a report that will form an integral part of your company’s continual improvement process.

How Non-Conformance Reports Can Help Your Business

There are many benefits of using Non-Conformance reports in a business. These include: Prevent customer complaints..

What Are the Most Common Causes of ISO 9001 Non-Conformance?

Causes of ISO 9001 non-conformance can vary from things like lack of employee training, inadequate management commitment, ineffective process controls, insufficient documentation, resistance to change, and poor communication.

Kaizen Continuous Improvement

Fundamental to Kaizen continuous improvement is the philosophical belief that everything can be improved. When using this approach, incremental changes gradually add up to substantial changes over the long term.

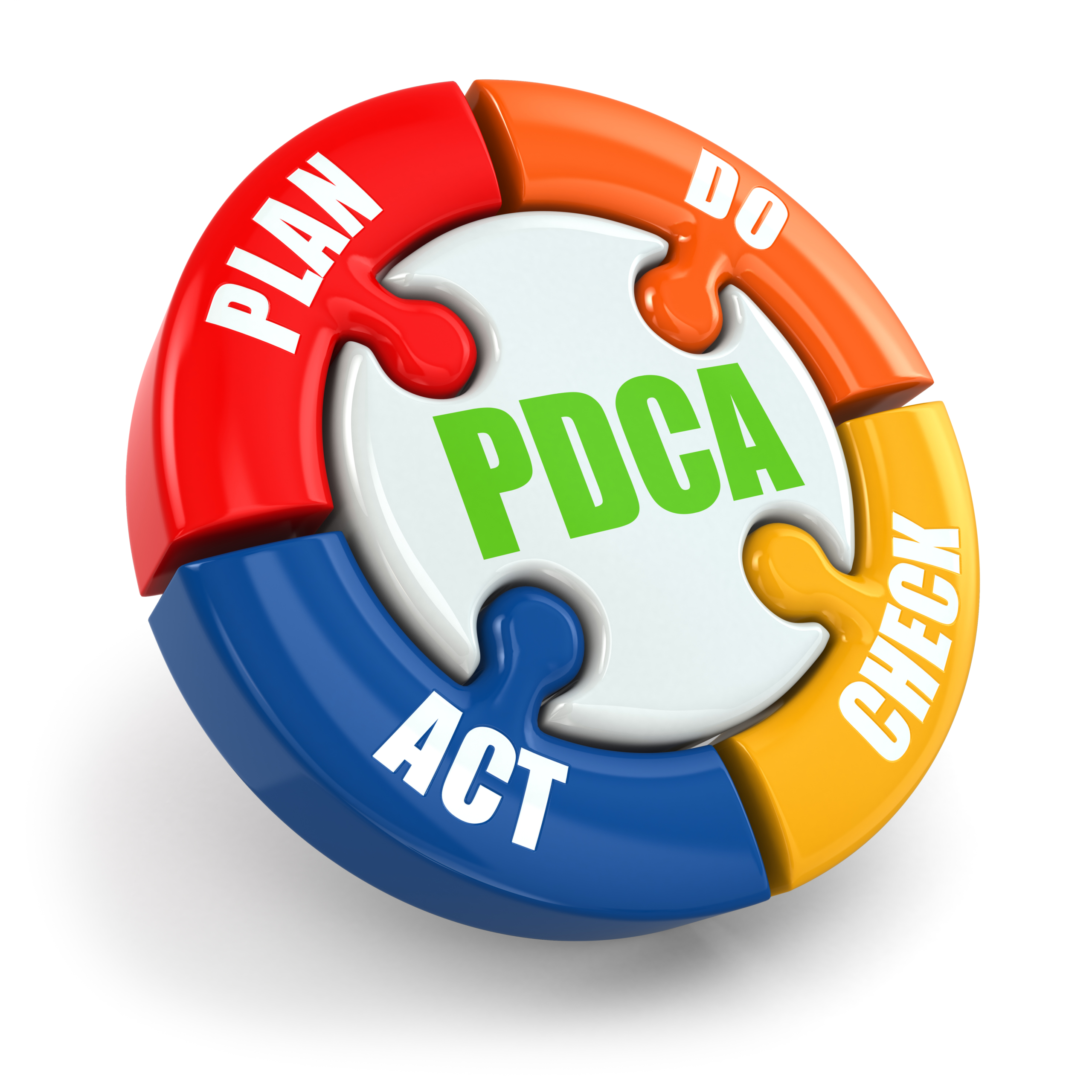

PDCA Cycle

he Plan-Do-Check-Act (PDCA) cycle is a scientific method for iterative problem-solving that is used to continuously improve products and processes by identifying improvement opportunities. It is also referred to as the Shewhart cycle or the Deming cycle.

CAPA Records – The CAPA Process Explained

CAPA records and the CAPA process is often a big issue for ISO 9001-accredited companies. CAPA (corrective and preventive action) still remains one of the most cited areas for external audits during ISO QMS audits.

The Continuous Improvement Process Explained

In this article, we’ll give you continual improvement examples and techniques that will help you operate your business better.

Steps to Creating a Highly Effective Corrective Action Plan

A major function of a CAP (corrective action plan) is to prevent the same issues from occurring again. This leads to strengthened employee performances, products, and business processes to prevent errors that result in non-conformities. A CAP may for example address work instructions being misinterpreted, equipment failure, or a customer complaint.

Root Cause Analysis Explained

People often use root cause analysis in everyday situations as one of many analysis methods without realizing it.

A Guide to Non-Conformance Reporting (NCR)

Non-conformance Reporting is a process used by companies to keep track of issues and problems. Once they find out what causes these, they can then put steps in place to prevent them from happening again. The process is documented using NCRs (Non Conformance Reports).

Corrective Action and Preventive Action

Although corrective action and preventive action are two important quality system elements, people often get confused about which type should be used when.

What is Corrective Action?

Whenever a “nonconformity” or incident happens in the workplace, management needs to take action to fix the problem.

What Is Non-Conformance (Nonconformity)?

In the context of an ISO 9001 Quality Management System (QMS), a nonconformity, also known as a non conformance, is failing to meet a requirement, realize and define the problem, contain the problem, determine its cause and take appropriate action to prevent it from happening again.