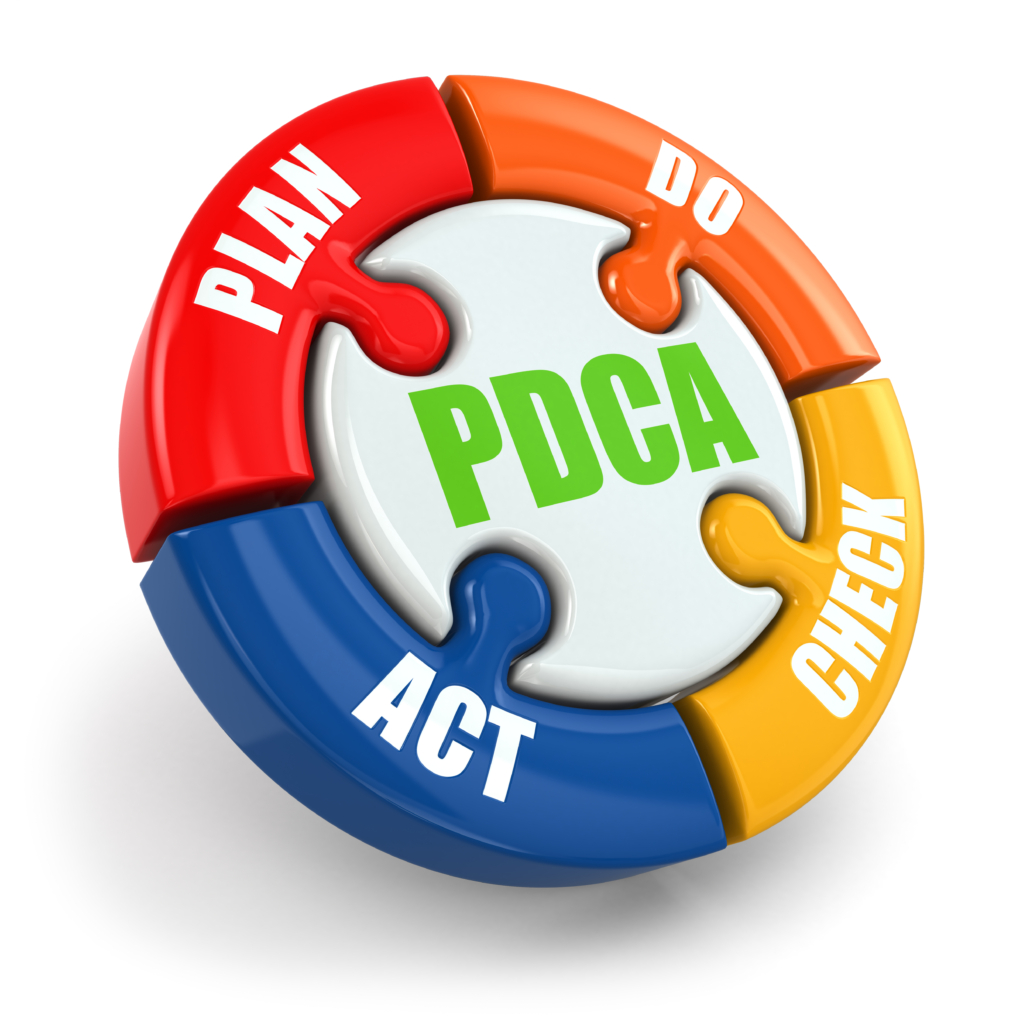

The PDCA Cycle (Plan-Do-Check-Act)

The Plan-Do-Check-Act (PDCA) cycle is a scientific method for iterative problem-solving. It is used to continuously improve products and processes by identifying improvement opportunities. The pdca cycle is also known as the Deming cycle, or sometimes the Shewhart cycle.

In this article, we’ll look at the four stages of the PDCA cycle. We will also discuss the benefits it will bring to your organization.

What Is the PDCA Cycle?

The Plan-Do-Check-Act cycle is a model that is often used to implement change. It is an essential component of the Lean manufacturing philosophy. It is also a key requirement for continuous improvement of processes and people.

The PDCA cycle was initially proposed by Walter Shewhart and William Deming later developed it. It eventually became a widely used framework for constant improvements in management, manufacturing, and many other areas.

PDCA is a simple four-step model that allows teams to improve processes while avoiding recurring mistakes.

PDCA Process History

Walter Shewhart, an American physicist and statistician is seen as the father of PDCA. Being passionate about quality improvement and statistical analysis, he created the foundation of PDCA and recorded it in numerous publications.

The first iteration consisted of a 3-step cycle that was repeated for process improvement. This is generally known as “the Shewhart cycle”.

The 3 phases of this cycle are:

- Specify

- Produce

- Inspect

William Deming was inspired by Shewhart’s cycle. Years later, he expanded the model into an improvement and learning cycle that consisted of the following 4 steps:

- Design

- Make

- Sell

- Test

In 1951 was by the Japanese Union of Scientists and Engineers (JUSE) redesigned this model. It then gradually morphed into what we know today as the PDCA cycle.

The 4 Steps of the Iterative Process

The Plan-Do-Check-Act cycle is an iterative process that is used to continually improve services, people, and products. It is an ongoing process that is nowadays also an integral part of Lean management. The PDCA model includes testing solutions, analyzing the results, and process improvement.

If you for example have numerous complaints from customers about your support team’s slow response rate, you need to improve the way the team works to improve customer satisfaction. That is where PDCA can be used.

Let’s examine the 4 steps in the PDCA process.

1. Plan

You will literally plan what must be done in the planning phase. Depending on the size of the project, planning can be a major part of the team’s actions. This stage will normally contain smaller steps that will allow you to build a proper plan with fewer potential failure points.

When doing this stage, make sure you have answered some basic questions:

- What is the core problem that needs to be solved?

- What resources are available?

- What resources are required?

- Using the available resources, what is the best solution to fix the problem?

- What are the goals?

- When will the plan be deemed to have been successful?

Remember that you and the team will likely have to go through the plan a few times before you can proceed to the next step. While in the planning stage, it’s useful to implement a technique to create and maintain open feedback loops. One such technique would be Hoshin Kanri Catchball. This will permit you to collect enough information before deciding to proceed.

2. Do

Once you have finalized the plan, it is time to do (take action). In this step, you need to apply everything that you’ve considered during the planning stage.

You should be aware that it is very likely that unexpected problems may be identified during this phase. This is why it’s a good idea to, where possible, implement the plan in a controlled environment on a small scale.

Standardization is also something that will help the team implement the plan smoothly. Ensure that all parties involved know their responsibilities and roles.

3. Check

The check phase is likely the most important one of the PDCA cycle. You need to pay appropriate attention to this phase if you want to clarify the plan, prevent recurring mistakes, and implement continuous improvement successfully.

This is also the time when you should audit the plan’s execution to verify if the initial plan actually worked. This will help the team to identify challenging parts of the current process and eliminate or modify them. If something does go wrong during the process, you have to analyze it and identify the root cause of the problem.

4. Act

The last stage of the PDCA cycle is the act phase.

If everything appears to be in place and the team has achieved the original goals, you need to proceed and apply the proposed solution.

If objectives are met it is appropriate to implement the whole plan and make the PDCA model the new standard baseline. Each time you repeat a standardized plan, you will however have to go through all the steps again and try to improve the process.

How Does PDCA and Continuous Improvement Benefit Your Business?

The PDCA cycle methodology is often used to improve quality and business processes, and solve problems. Organizations deploy this model to optimize their internal and external processes by eliminating any issues within the work process.

The cyclical nature of the model enables teams to identify and eliminate defects early in the process and then restart the cycle until the required outcome is achieved. This improves efficiency and eliminates elements that are not effective until the ideal solution has been identified.

Due to the PDCA’s continuous feedback loop, organizations can utilize the model to obtain relevant information before deciding whether to continue with a plan or to first improve it. This data-driven approach provides a good foundation for organizations to continuously improve their products, processes, people, and services.

When Should the PDCA Cycle Be Used?

A specific trait of PDCA is that it is very versatile. This characteristic means that it can be used across various organizations, businesses, individual teams, and departments. There are no limitations in terms of implementing it, and it may be applied in the following scenarios, amongst others:

- Optimizing current products or processes

- Developing new products or services

- Exploring new continuous improvement opportunities

- Starting a new process improvement project

- Detecting issues with processes and working toward eliminating them

- Implementing changes

PDCA Cycle Examples

Example #1: Nike

Nike implemented Lean manufacturing as part of their business believing that the philosophy of continuous improvement is the foundation of empowering their workforce and their advanced sustainable manufacturing. Nike implemented the PDCA cycle as part of their training on process improvement to improve the working environment and being able to deliver high-quality products while eliminating activities that did not add value. (Source: OpEx Learning)

Example #2: Lockheed Martin

Lockheed Martin is involved in the aerospace industry and is a shiny example of how the Kaizen methodology can bring improvements to the operations of a company. Implementing the PDCA cycle has resulted in their projects being standardized while the quality of the products and services was increased by targeting problems and solving them via multiple iterations. In the period between 1992 and 1997, significant improvements were noticed when the company reduced manufacturing costs by 38%, reduced inventory by 50%, and reduced delivery time to 21.5 months from 42 months. (Source: 6Sigma.com)

Example #3: Nestlé

Nestlé has defined the all-time mission of reducing waste in all aspects of work. To achieve this goal, the company implemented the concept of Lean management successfully. They also introduced the Kaizen method to ensure that all individuals in the company buy into the concept of continuous improvement. To follow the Kaizen principle that every slight improvement should be implemented to reduce costs and increase efficiency, the company uses the PDCA cycle to stipulate guidelines. (Source: TheGemba.com)

Nestlé Waters is also an example of how techniques like Value Stream Mapping (VSM) can help depict the flow of information and materials from raw materials to the final products. The bottling plant has seen a significant increase in process efficiency as a result of implementing the process.

Continual Improvement through PDCA

The PDCA cycle is a simple yet powerful framework that can be used to fix issues on any organizational level.

The cyclic approach helps teams identify and test solutions and then improve them via a cycle to reduce waste.

The PDCA cycle includes a compulsory commitment to continual improvement and can have a huge positive impact on both efficiency and productivity.

Do however remember that the PDCA process needs some time, and it might not be suitable for resolving urgent problems.

PDCA FAQs

What is the difference between Kaizen and PDCA?

Both Kaizen and PDCA aim to achieve continuous improvement via incremental, small changes and create an organizational culture of Lean problem-solvers and thinkers. The Kaizen methodology includes doing small experiments, monitoring the results, and then adjusting when improvements become apparent. The PDCA cycle offers a framework to apply this concept in practice and that can be used to continuously promote improvement.

What is the difference between PDSA and PDCA?

PDSA stands for “Plan-Do-Study-Act, while “PDCA stands for “Plan-Do-Check-Act”. Although both these 4-step models are aimed at improving processes, one stage in each cycle is different.

At the “Study” stage in the PDSA cycle, the results of any change applied at each step should be analyzed in depth, leading to long-term process improvements. In contrast, at the “Check” stage in PDCA, the team must audit the plan’s execution and determine if the initial plan worked. Either way, you can use both models by checking or studying the results obtained from tests.

What is the difference between Six Sigma and PDCA?

Six Sigma is a process improvement and quality approach that gives organizations a set of techniques and tools to increase the quality of services and products, as well as to improve work performance. The PDCA cycle is one of the tools included in that toolset.

Although Six Sigma provides a framework to determine what slows a process, techniques such as PDCA explain the steps used to identify and eliminate problems.

How Does PDCA Fit into ISO Quality Management Systems?

Although the various ISO system specifications require that an organization improve continually, they do not specify how this should be done or which tools to use.

The PDCA cycle can be used as a framework for improvement ideas to meet the continuous improvement requirement of ISO 9001 and other Quality Management systems. Doing this would however not eliminate the need to implement non-conformance reporting or preventive and corrective actions also specified by ISO 9001. Corrective actions software can be used to make implementation of those ISO elements easy and effective.